Our Strengths

-

28-year experience in the industry

-

Customization on demand for all products

-

The only one in the industry listed in the Catalogue of National Key Energy Conservation and Low-Carbon Technologies for Promotion

-

Benchmarking enterprise in the sectors of wear-resistant castings and metal surface modification technology

-

Pioneer of comprehensive and efficient ball mill energy saving technology solution

-

Member of drafting committee of national standards for chromium-manganese-tungsten wear-resistant castings

Products

-

Grinding ball (forged)

Grinding ball (forged)1、Chromium-manganese-tungsten wear-resistant cast iron grinding balls (forged)

Transcending the original R&D concept, we have refined the carbide grains of materials through the joint action of chromium, manganese and tungsten in terms of metal element selection and ratio, metallographic structure, etc. As a result, (CrMnW)7C3 special carbide is formed, which greatly improves wear resistance, reduces out-of-roundness rate, stabilizes grinding ball gradation, and increases the utilization rate of small diameter grinding balls

2、Low-manganese wear-resistant cast iron grinding balls (forged)

3、All-chromium (Cr0-Cr25) wear-resistant cast iron grinding balls (forged)

4、Materials to be customized following the needs of customersView Details

-

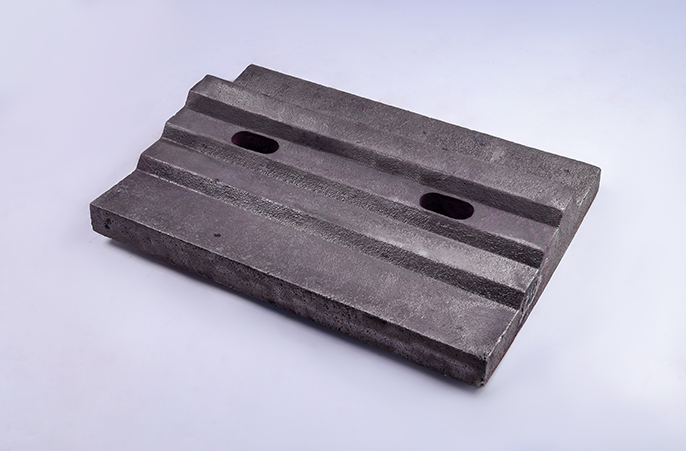

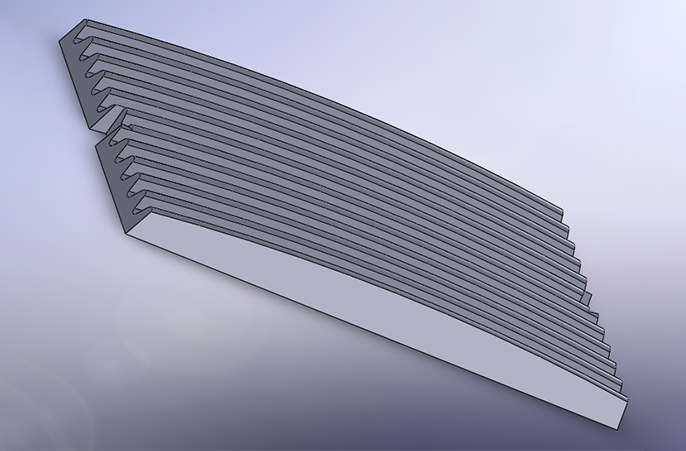

Integral step liner

Integral step linerIt is customized in accordance with material characteristics to make many grinding bodies fall to the position with the highest grinding efficiency, thus greatly improving the grinding efficiency of the ball mill, improving the capacity of the ball mill, and reducing the power consumption of the same. This product is a key new product in China.

Materials for liner:

1、Manganese-silicon-chromium-molybdenum wear-resistant cast steel liner: It is an alloy wear-resistant liner with high strength and hardness, with the hardness (HRC) of more than 50. Therefore, it is not easy to deform compared with high-manganese steel in application, and the wear resistance is improved by more than 30%;

2、Manganese-vanadium-titanium wear-resistant cast steel Liner: Compared with the high-manganese steel liner, it added the rare alloys - vanadium and titanium, resulting in better impact hardening capacity and higher wear resistance;

3、 Cr5, Cr15, Cr18…… and other high-chromium cast iron series liners;

4、 Materials to be customized following the needs of customers.View Details

-

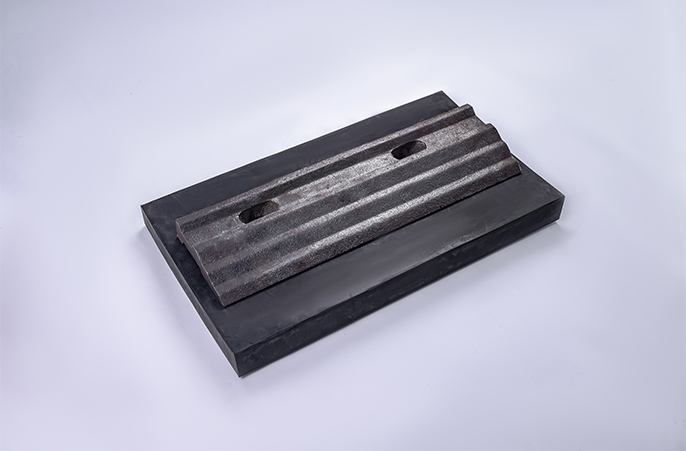

Wear-resistant rubber and wear-resistant cast steel combined liner

Wear-resistant rubber and wear-resistant cast steel combined linerThe base plate is made of special wear-resistant rubber, and the wave crest is made of wear-resistant metal material.Therefore, it not only has the functions of energy saving and productivity improvement, but also features light weight, high wear resistance, corrosion resistance, impact resistance, easy installation and low noise among other benefits.

View Details

-

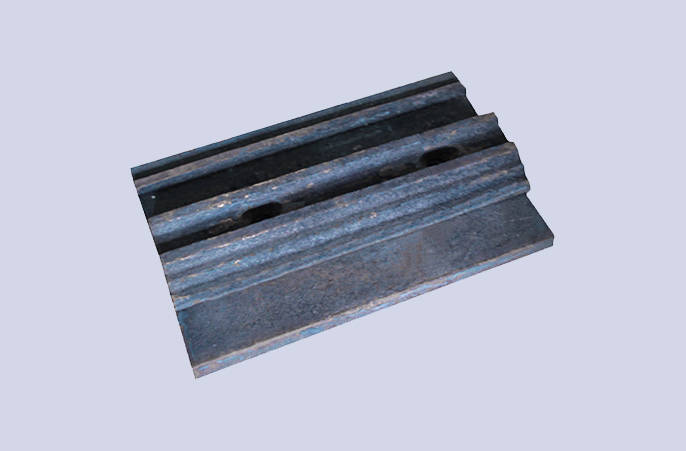

Split step liner

Split step linerThe step liner is a split combined liner, and the wave crest is designed separately from the base plate, thus it has the functions of energy saving and productivity improvement. Generally, only one base plate needs to be replaced for 2-3 times of wave crest replacement, which can greatly reduce the material consumption and cost of liner for ball mill.

View Details

-

Concrete pump pipe casting

Concrete pump pipe castingRelying on the CrMnW high-chromium cast iron materials developed independently by the Institute of Wear-resistant Materials, Central South University, Huamin Holdings has made castings lighter with better performance in wear and pressure resistance by optimizing the material formulation and heating processing. The pump pipes can function in a more stable manner within a longer service life with carbon emission lowered. In this way, the consumption of pump pipe spare parts can be reduced, therefore saving the cost to use.

View Details

-

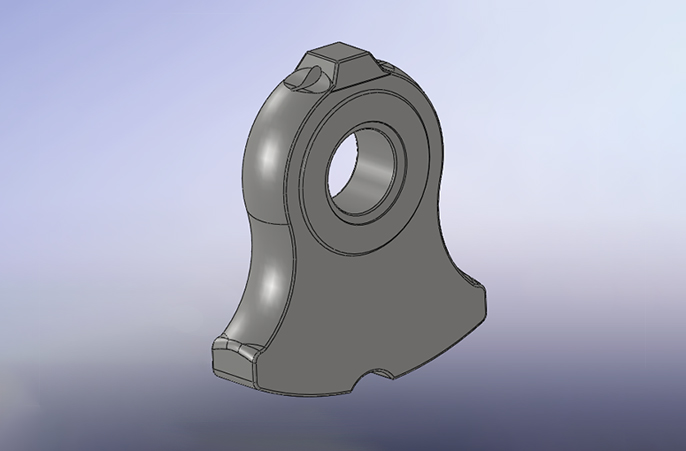

Spare parts of mine crusher

Spare parts of mine crusherAs low alloy steel products, the main parts are special castings, requiring good mechanical properties under ultra-low temperature.

View Details

-

Spare parts for metal crusher

Spare parts for metal crusherCast out of bronze scrap steel containing vanadium and titanium wear-resisting elements, these spare parts are divided into high manganese steel and low alloy steel. For low alloy steel castings, the wear resistance is 1.5-2 times better than ordinary castings at extremely low temperatures. The products have been certified by the ISO9001 quality management system, with a qualified rate of 100%.

View Details

Contact Us

We prioritize customer value and devote to creating long-term value for customers with our professional, reliable and all-round consulting services in time.